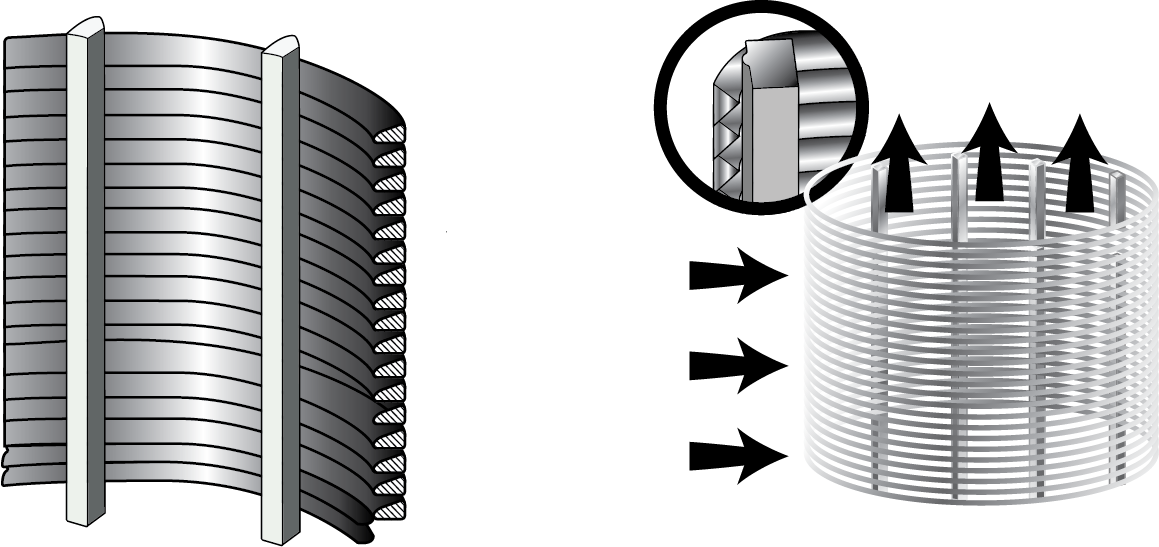

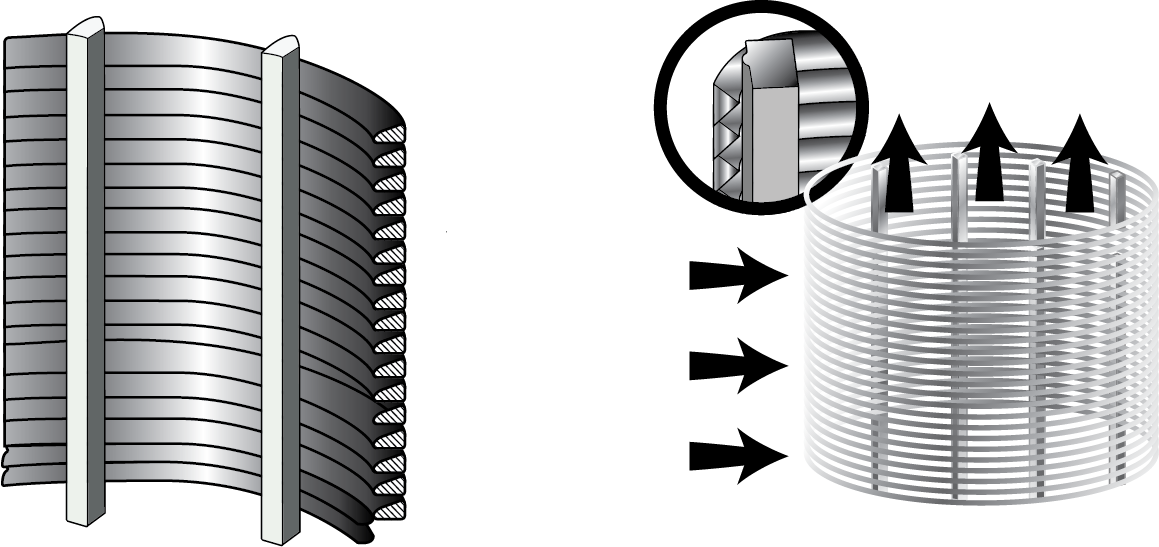

A wedge wire screen tube is also called a round slot tube. It is made of stainless steel wire, because of its outstanding chemical stability and corrosion resistance.

What are the advantages of using a wedge wire tube?

1. The wedge wire-type element of continuous rope or wire creates a V-shaped filter element that prevents clogging with small particles and therefore does not clog and has a better filtering function.

2. The continuous rope and support rods are welded and this makes them more robust and therefore have a longer service life.

3. They can be ordered with different openings, diameters, and types of connections as required by the customer.

4. In addition, the longitudinal support bars and continuous grooves create a mesh with good pressure resistance performance.

When should the wedge wire filter pipe be used?

1. When uninterrupted flow is required as the V-shaped profile prevents clogging.

2. When a water well screen with an even and efficient flow is required as it has a continuous slot opening.

3. When a water well screen is required with features such as backwashing, safety, and reliability when in use as it has ladder welded wire screens.

Applications of wedge wire wedge wire screen tube

- Petroleum industry. Oil filtration.

- Water treatment industry. Desalination of seawater, treatment of industrial water, and domestic water. Water softening treatment.

- Chemical industry. End products of chemical organic solution filtration, such as acid, alkali liquid filtration, alcohol, and other products filtering.

- Hydro-geological exploration.

- Drilling construction.

- Geothermal development.

- Catalytic reformer.