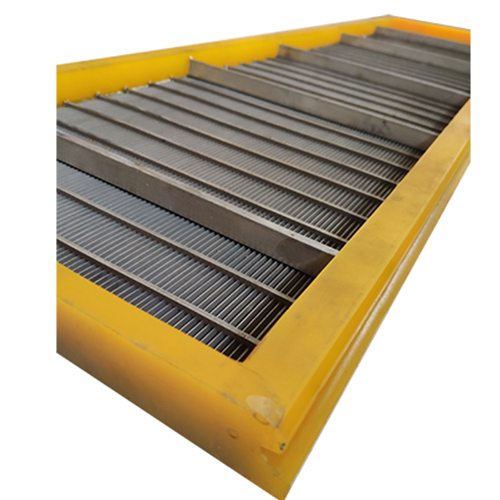

Polyurethane screens are made of strong and high-strength polyurethane compounds with wear-resistant and corrosion-resistant.

Polyurethane screens have a lifespan of up to 10 times longer than steel screens. Therefore they are an effective replacement for steel woven wire screens.

Polyurethane screen decks provide low noise levels and excellent filtration efficiency. This makes them ideal for screening applications such as mining and aggregate processing.

We provide polyurethane screens in different sizes, shapes, patterns, and apertures.

Advantages of Polyurethane Screens

1. The screens are durable and can withstand wear, impact, and corrosion, minimizing downtime and maintenance costs.

2. Their flexible structure allows the screen to flex, helping to reduce clogging and blinding.

3. Lighter than standard screens, it helps reduce energy consumption and is more cost-effective.

4. Various types of polyurethane screen plates can be customized for a wide range of applications.

6. Simple assembly and disassembly of modules.

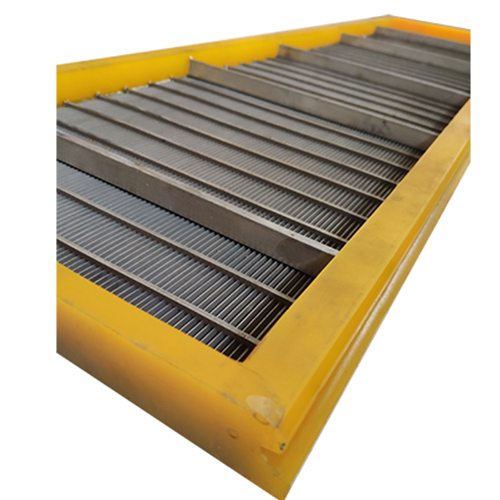

Specification and Custom for Polyurethane Screens

Polyurethane Screen is available in different aperture sizes, configurations, and panel dimensions to suit your specific requirements.

Opening Range: 1.1 – 160 mm(includes square and rectangular opening screens)

Maximum Screen Size: 1900 x 30000mm

Standard Screen Thickness: 20-60mm

Application of Polyurethane Screens

Polyurethane Screens can be used in aggregate processing, washing applications, cement manufacturing, asphalt plants, mining applications, and other industries.

They also play an important role in these industrial processes: screening, sizing, separating, grading, shifting, and washing.

Contact us to customize polyurethane screens suitable for your industry! We promise the lowest price!

Contact us Now