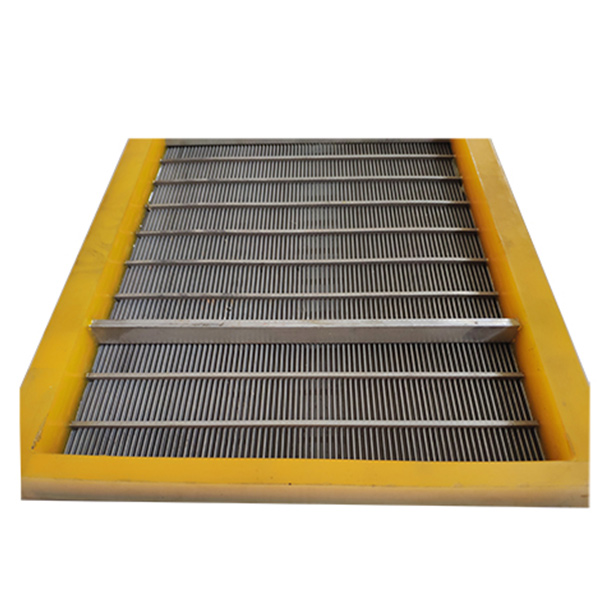

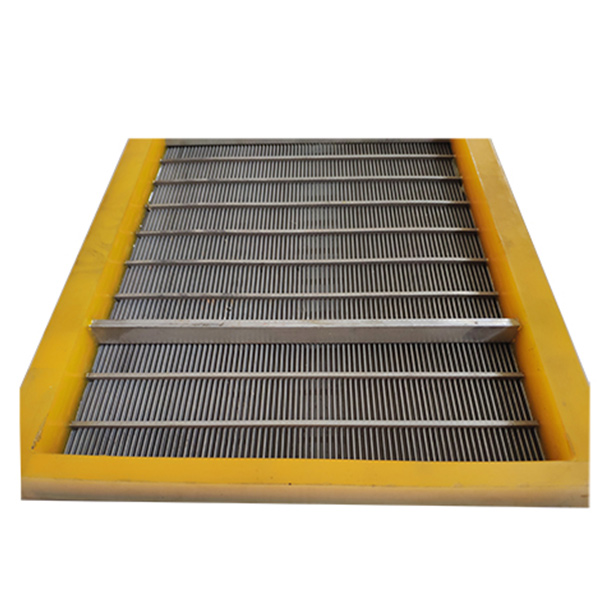

Hangsheng polyurethane dewatering screen panels offer superior performance, durability, superior screening efficiency, self-cleaning properties, noise reduction, customization options, and environmental sustainability. This makes polyurethane screens a preferred choice for material separation applications.

In this blog post, we will explore the features and benefits of polyurethane screen panels, shedding light on how they enhance screening efficiency and revolutionize the industry.

Features and Benefits of Polyurethane Screen Panels

1. Enhanced Durability:

Polyurethane vibrating screen panels are highly durable and capable of withstanding demanding operational conditions. Their exceptional resistance to abrasion, impact, and corrosion allows them to maintain their structural integrity even in harsh environments. Compared to traditional screen panels made from rubber or steel, polyurethane panels offer a longer lifespan, reducing downtime and replacement costs.

2. Superior Screening Efficiency:

One of the key advantages of polyurethane screens is their ability to improve screening efficiency. The panels are designed with precise apertures and a high open area, allowing for efficient material separation. The accurate opening sizes ensure optimal sizing and classification of materials, resulting in improved productivity and reduced energy consumption.

3. Self-Cleaning Properties:

Polyurethane frame screen panels are renowned for their self-cleaning capabilities. The unique design and flexibility of the panels prevent clogging, blinding, and pegging issues commonly associated with other screen materials. The panels' anti-clogging properties enhance screening performance by maintaining consistent material flow, ensuring uninterrupted operation, and minimizing downtime for cleaning.

4. Noise Reduction:

In addition to their functional advantages, polyurethane screen panels also contribute to a quieter working environment. The panels' flexible nature and shock-absorbing properties help reduce vibration and noise generated during the screening process. This not only enhances operator comfort but also improves overall workplace safety.

5. Customization and Versatility:

Polyurethane dewatering screen panels offer excellent customization options to meet the specific needs of various applications. Manufacturers can tailor the panel design, aperture size, and pattern to suit the unique requirements of different materials and operational conditions. This versatility makes polyurethane screen panels suitable for a wide range of industries, enabling efficient material separation across diverse applications.

6. Environmental Sustainability:

Many polyurethane screen panel manufacturers prioritize sustainability by using eco-friendly materials and manufacturing processes. Polyurethane itself is a recyclable material, contributing to reduced waste and environmental impact. Furthermore, the longer lifespan of polyurethane screen panels reduces the need for frequent replacements, leading to resource conservation and a lower carbon footprint.

Hangsheng can provide and custom-design various types of polyurethane screens, including welded wedge wire screens with polyurethane edges. Contact us to learn more about our wedge wire screen products!

Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Stainless Steel Parabolic Screen for Mineral Processing

Stainless Steel Parabolic Screen for Mineral Processing