Understanding Mineral Processing

Before delving into the specifics of the stainless steel parabolic screen, it's essential to grasp the context of its application. Mineral processing involves a series of physical and chemical processes to extract valuable minerals from ores. These ores are typically obtained from mines and undergo crushing, grinding, separation, and concentration processes to yield the desired minerals.

Efficiency in mineral processing is paramount, as it directly impacts the economic viability of mining operations. Any improvement in efficiency, no matter how incremental, can translate into substantial cost savings and enhanced productivity.

One critical aspect of mineral processing is the screening stage. After initial crushing and grinding, the ore mixture contains a variety of particle sizes, ranging from fine powders to coarse aggregates. Screening is employed to separate these particles according to size, ensuring that only the desired fractions proceed to subsequent processing steps.

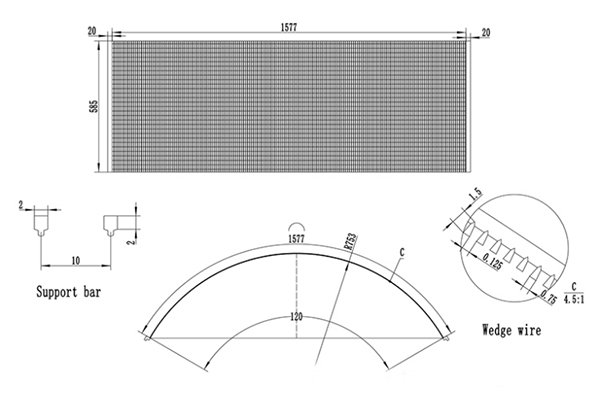

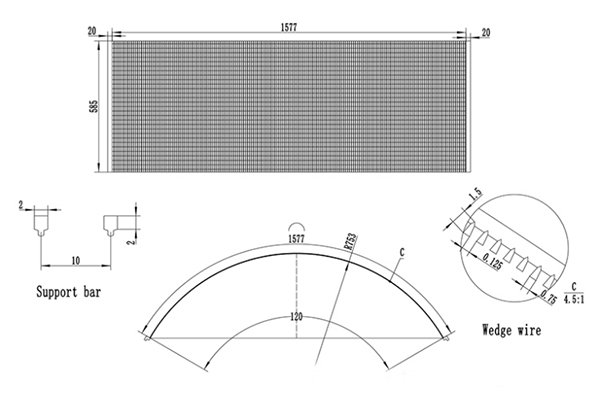

Parabolic screens are important screening equipment in mineral processing. It effectively compensates for limitations such as general screen clogging, blindness, and rapid wear.

There are several benefits of stainless steel parabolic screens:

▪ Self-Cleaning Action:

The parabolic shape of the screen promotes the continuous movement of particles across its surface. This motion helps prevent clogging and blinding, reducing downtime for maintenance and cleaning.

▪ Enhanced Screening Efficiency:

The curved screen promotes improved particle stratification, allowing for more precise separation according to size. This results in higher screening efficiency and a more uniform product.

▪ Durability and Longevity:

Constructed from high-quality stainless steel, these screens exhibit exceptional strength and resistance to corrosion and abrasion.

▪ Versatility:

Stainless steel parabolic screens can be customized to suit specific application requirements, including varying sizes, aperture configurations, and screen materials. This versatility ensures compatibility with a wide range of ores and processing conditions.

The benefits of stainless steel parabolic screens extend beyond mineral processing, finding application in diverse industries such as agriculture, food processing, and wastewater treatment. Welcome to contact us by WhatsApp at 86 13653285589 to custom design our ss parabolic screens for mineral processing!

Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Flat Wedge Wire Screen Panel: Design, Advantages, Applications

Flat Wedge Wire Screen Panel: Design, Advantages, Applications