In various industries such as mining, agriculture, water treatment, and food processing, filtration is a critical process that removes impurities and unwanted particles from liquids and solids. One innovative and efficient filtration solution that has been gaining popularity is the Parabolic Screen, also known as the Rundown Screen, manufactured by Hangsheng Filter. In this blog post, we will explore this cutting-edge filtration technology's features, benefits, and applications.

What is a parabolic screen?

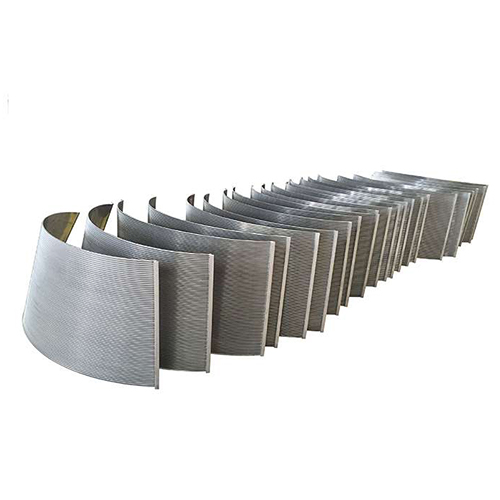

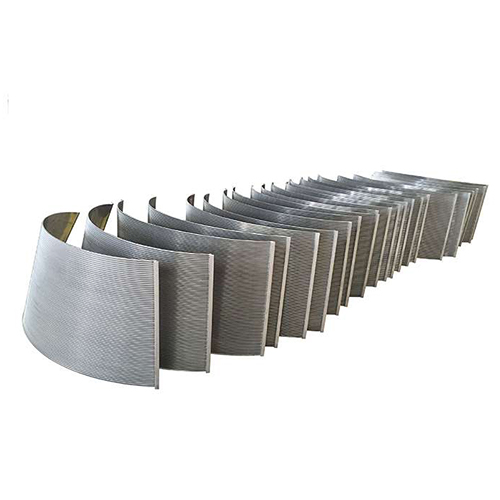

The Parabolic Screen, sometimes referred to as the Rundown Screen or parabolic rundown screen, is a speci alized type of static screen used for solid-liquid separation in various industrial applications. It consists of a curved, slotted screen surface that allows liquids to pass through while capturing and retaining solid particles. The parabolic shape of the screen is designed to enhance the efficiency of the filtration process, making it more effective than traditional flat screens.

Features and benefits of parabolic screen filters

Parabolic screen filters offer several unique features and benefits that make them highly efficient and sought-after solutions for solid-liquid separation in various industrial applications.

1. Precise Slot Openings: The wedge wire curved screens are available in various slot sizes, which can be tailored to specific filtration requirements. The precise slot openings allow for accurate separation of solids from liquids, ensuring a high-quality filtrate.

2. Self-Cleaning Mechanism: Parabolic screens are equipped with a self-cleaning mechanism. The curved design allows captured solids to slide down easily, preventing clogging and ensuring continuous operation without the need for frequent manual cleaning.

3. Versatility: The parabolic rundown screen is highly versatile and can be customized to suit various applications and industries. Different slot sizes and screen materials can be used to accommodate specific filtration requirements, making it a suitable solution for a wide range of processes.

4. Reduced Maintenance and Downtime: The self-cleaning mechanism minimizes the risk of clogging, reducing the need for frequent maintenance and downtime. This feature is particularly beneficial in continuous operation scenarios.

5. Customization: These curved screens can be customized to suit different applications and industries. The flexibility to adapt the screen material and slot size makes them versatile and adaptable to various solid-liquid separation processes.

Typical Applications of parabolic screen design

1. Mining and Minerals: Parabolic Rundown Screens are used in the mining industry for dewatering and separating minerals from slurries, improving the efficiency of mineral processing operations.

2. Agriculture: In the agricultural sector, the curved screen is utilized for irrigation water filtration, separating organic matter and debris from water sources, which helps maintain the quality of water used for irrigation.

3. Food Processing: The food industry uses wedge wire parabolic screens to filter liquids, such as juices and sauces, removing solid particles and ensuring a smooth and pure end product.

4. Water Treatment: Municipal and industrial wastewater treatment facilities employ parabolic screen filters for primary and secondary screening, reducing the load on downstream treatment processes.

The Parabolic Screen, or Rundown Screen, offered by Hangsheng is a cutting-edge solution for efficient solid-liquid separation in various industries. With its innovative design, self-cleaning mechanism, and versatile applications, it has proven to be an essential tool for enhancing filtration processes and improving overall operational efficiency.

Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Stainless Steel Parabolic Screen for Mineral Processing

Stainless Steel Parabolic Screen for Mineral Processing