The choice between a wedge wire screen and a perforated screen depends on the specific application and requirements. Both types of screens have their advantages and disadvantages, and the superior option varies depending on factors such as the intended use, desired performance, and environmental conditions. Here are some considerations for each type of screen:

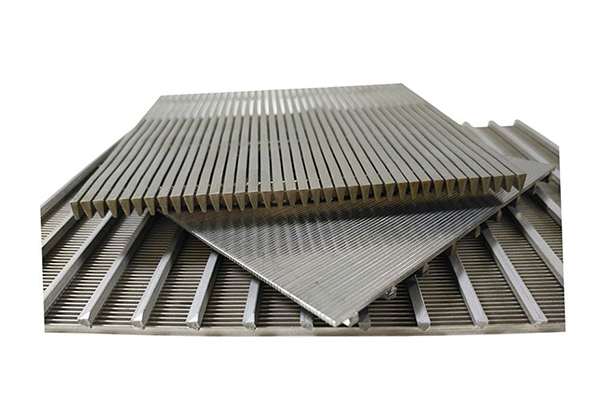

▪ Wedge Wire Screen

| Advantages of wedge wire screen |

Disadvantages of wedge wire screen |

| Provides a continuous slot design, allowing for efficient filtration and screening. |

Typically, it is more expensive to manufacture and install than perforated screens. |

| Offers better resistance to clogging compared to perforated screens, making it suitable for applications with fine or sticky materials. |

May require more maintenance, as fine particles can accumulate in the slots over time. |

| It can be custom-designed with various slot sizes, shapes, and profiles to match specific filtration requirements. |

Limited in open area percentage, which can impact flow rates in some applications. |

| Suitable for applications that require precise particle separation and dewatering. |

Wedge wire screens are often preferred for applications where fine particle separation, efficient dewatering, and resistance to clogging are crucial, such as in water treatment, mining, and food processing industries. |

High-Quality Wedge Wire Screen Manufacturer and Factory

Looking for a reliable and high-quality wedge wire screen manufacturer? Our factory offers top-notch wedge wire screens at competitive prices. Contact us for customized solutions.

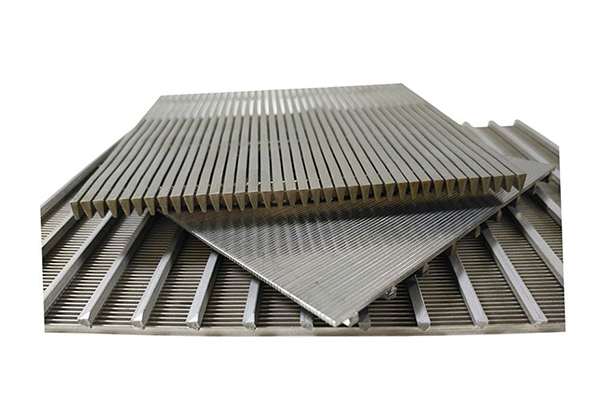

▪ Perforated Screen

| Advantages of perforated screen |

Disadvantages of perforated screen |

| Generally more cost-effective to manufacture and install than wedge wire screens. |

May not be as efficient as wedge wire screens in fine particle separation or dewatering applications. |

| Offers a high open area percentage, allowing for high flow rates in applications that require it. |

Prone to clogging when used with materials that have a tendency to accumulate in the perforations. |

| Requires less maintenance, as there are no slots that can become clogged with fine particles. |

Perforated screens are often chosen for applications where cost-effectiveness, high flow rates, and minimal maintenance are more critical than precise particle separation, such as in agriculture, HVAC systems, and some industrial sieving processes. |

In summary, neither wedge wire screens nor perforated screens are universally better than the other. The choice depends on the specific requirements and constraints of your application. It's essential to consider factors such as the nature of the material being screened, the desired filtration efficiency, cost considerations, and maintenance requirements when selecting the appropriate type of screen.

In summary, neither wedge wire screens nor perforated screens are universally better than the other. The choice depends on the specific requirements and constraints of your application. It's essential to consider factors such as the nature of the material being screened, the desired filtration efficiency, cost considerations, and maintenance requirements when selecting the appropriate type of screen.

Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Stainless Steel Parabolic Screen for Mineral Processing

Stainless Steel Parabolic Screen for Mineral Processing