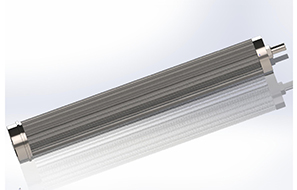

Wedge wire pressure filter tubes are important equipment and solution for petrochemical water primary filtration. It is designed to withstand high-pressure levels and high corrosion characteristics, making it ideal for the primary filtration of petrochemical water.

Hangsheng provides wedge wire pressure filter tube customization and design services all over the world.

WhatsApp: 86 13653285589

This blog post will discuss the importance of primary filtration of petrochemical water and the role of our pressure filter tubes in petrochemical water filtration.

Why Primary Filtration of Petrochemical Water?

1. Primary filtration is a critical step in water treatment to ensure the quality, safety, and reliability of the water used.

2. Primary filtration acts as a physical barrier to prevent any large particles or debris from entering the system and contaminating the water. Can effectively prevent damage to the system, resulting in costly repairs and downtime.

3. Helps reduce the risk of system corrosion.

What is the role of pressure filter tubes in petrochemical water primary filtration?

1. Our wedge wire pressure filter tubes perform the role of filtration first in petrochemical water, providing an efficient method of removing large particles from water.

2. The pressure filter tube is also a method of flow regulation that controls the flow rate of water through the filtration system to help petrochemical plants operate efficiently.

Overall, pressure filter tubes are an excellent choice for petrochemical water primary filtration. Welcome to contact us to get a free quote!  Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Stainless Steel Parabolic Screen for Mineral Processing

Stainless Steel Parabolic Screen for Mineral Processing