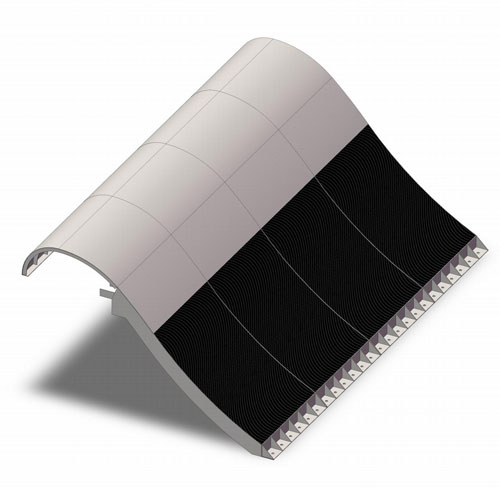

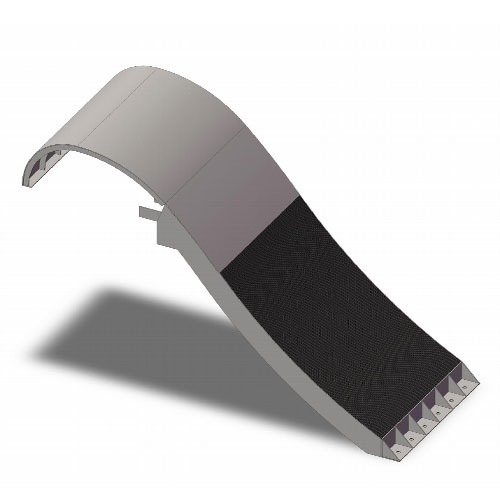

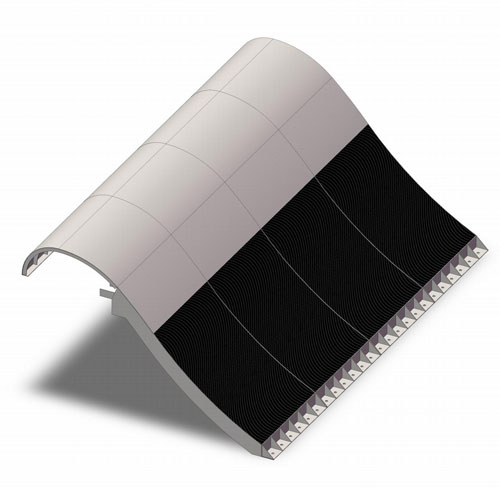

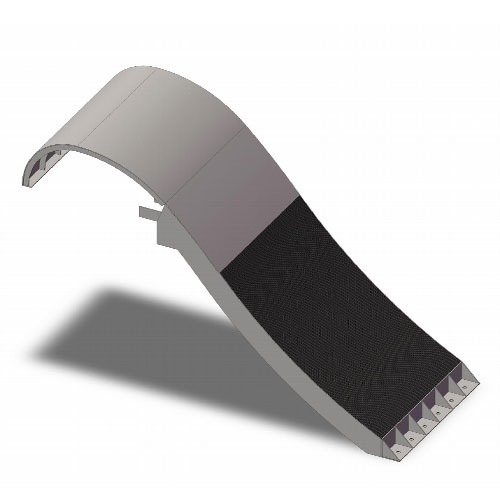

A Coanda screen is a type of water intake screen used in hydroelectric power plants, water treatment plants, and other industrial applications. It is designed to prevent debris, such as leaves, sticks, and fish, from entering the intake pipes and causing damage to the equipment.

Principle of Coanda Screens

The Coanda screen operates by utilizing the Coanda effect, which is the tendency of a fluid to adhere to a curved surface, to direct the flow of water towards the screen.

The Coanda screen also referred to as the Coanda intake screen, is typically constructed from durable materials such as stainless steel and is designed to be easily cleaned or replaced as required. The size of a Coanda screen is determined by the specific application and the flow rate of the water being screened.

Benefits of Coanda screen

The Coanda intake screen offers several benefits in industrial applications.

1. Efficient debris removal: The Coanda effect allows the screen to effectively capture debris, such as leaves, sticks, and fish, without impeding the flow of water.

2. Self-cleaning function and reduced maintenance costs: The Coanda screen is designed to be easily cleaned or replaced, reducing the need for costly maintenance and downtime.

3. No power requirements, energy saving.

4. Improved equipment protection: By preventing debris from entering the intake pipes, the Coanda screen helps to protect equipment from damage and extend its lifespan.

5. Long service life.

Manufacturing of Conada Screens

We are a professional Conada screens factory in China. We have a complete and standard Conada intake screen manufacturing process.

1. Material selection: The screen is usually made from durable materials such as stainless steel, which can withstand harsh industrial environments.

2. Cutting and shaping: The material is cut and shaped to the desired size and shape using equipment such as laser cutters or water jets.

3. Welding: The individual pieces of the screen are welded together to form a single unit.

4. Surface treatment: The screen is treated with a surface coating or finish to improve its resistance to corrosion and other forms of wear and tear.

5. Quality control: The finished screen is inspected to ensure that it meets the required specifications and standards.

All in all, the Coanda intake screen is a reliable and cost-effective solution for protecting equipment and ensuring the smooth operation of industrial applications. Welcome to contact us to learn more! WhatsApp: 86 13653285589

Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Stainless Steel Parabolic Screen for Mineral Processing

Stainless Steel Parabolic Screen for Mineral Processing