Materials: high quality standard stainless steel 304, 316, 316L, 321, and others.

Slot size: custom as your need.

Tasks: provide reliable support and filtration performance in brewing, distillation, and enology.

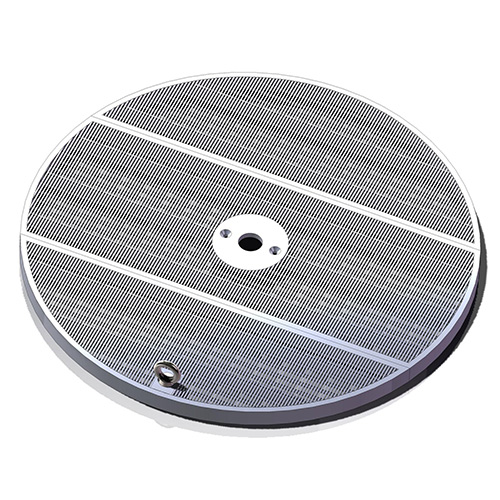

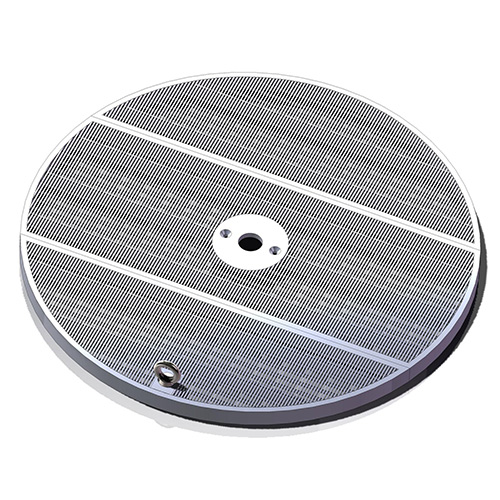

A false bottom is a perforated plate or screen that sits at the bottom of your mash tun. Its purpose is to separate the grain from the wort (the liquid that will become beer) during the sparging process. The holes in the false bottom allow the wort to flow through while keeping the grain in the mash tun. This is important because if the grain gets into the boil kettle, it can cause off-flavors and cloudiness in the finished beer.

That is why we need a false bottom screen for the beer mash tun. It is worth noting that we provide wedge wire false bottom screens for filter mash tun instead of perforated ones.

There are two types of false bottom screens for filtering the mash tun: wedge wire false bottoms and perforated false bottoms. While both types of screens serve the same purpose, there are some key differences between them.

1. Wedge wire screen filter false bottom is known for its strength, durability, and reliability. Wedge wire screens are also known for their excellent filtration performance, as they allow for a more even flow of liquid through the screen. This results in a more efficient filtration process and a higher-quality end product.

2. While perforated false bottom screens are less expensive than wedge wire screens, they are also less durable and reliable. Perforated screens are also known for their uneven flow of liquid, which can result in a less efficient filtration process and a lower-quality end product.

Overall, wedge wire false bottom screens are the preferred choice for brewers who value strength, quality, and reliability in their filtration equipment.

Contact us

WhatsApp: 86 13653285589

Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Stainless Steel Parabolic Screen for Mineral Processing

Stainless Steel Parabolic Screen for Mineral Processing