The header lateral screen consists of a series of wedge wires that form a precise V-shaped profile, creating a durable and efficient filtering surface. The design effectively separates solids, liquids, and gases while ensuring uniform flow distribution.

Our header laterals are widely used in equipment such as ion exchange units, clay and sand filtration systems, carbon towers, and power plant water systems.

Where on the vessel internals is the wedge wire header lateral installed?

The wedge wire header lateral is typically installed within the vessel internals, specifically in a strategic position where optimal filtration, distribution, or separation of solids, liquids, or gases is required. Common installation locations include near entry or exit points.

The vessel's specific application and engineering requirements will dictate the precise placement of the wedge wire header lateral within the vessel internals.

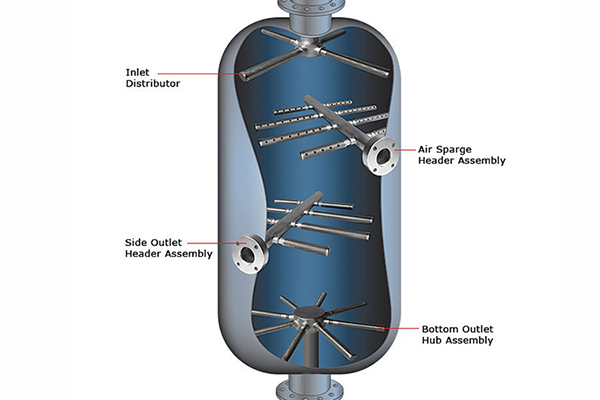

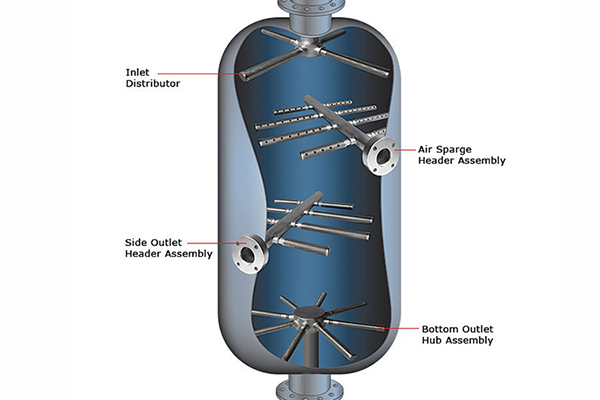

Various Types of Wedge Wire Screen Header Lateral for Vessel Internals

▪ Wedge Wire Screen Collector with Hub Spokes-Effective Distribution and Collection

A wedge wire collector with hub spokes is installed on the top or bottom container and is suitable for smaller vertical vessels. Each of our hubs and lateral can be customized for specific applications to effectively collect and evenly distribute media.

▪ Header Lateral Assembly- Designs For Horizontal Vessels

The header laterals assembly consists of a sequence of wedge wire screen laterals affixed to a central header. It can be side-mounted or centrally mounted and provides the most efficient even distribution or collection for horizontal vessels.

We provide various types and sizes of wedge wire screen header lateral for vessel internals. Contact us by email: [email protected] or WhatsApp: 86 13653285589.

Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Stainless Steel Parabolic Screen for Mineral Processing

Stainless Steel Parabolic Screen for Mineral Processing