In the realm of chemical and industrial processes, resin mixing plays a pivotal role in the production of various materials, ranging from plastics to adhesives. Achieving optimal mixing efficiency is crucial for ensuring product quality and minimizing production costs. A critical factor that significantly influences the mixing process is the selection of filtration systems.

Understanding Resin Mixing

Resin mixing entails the amalgamation of diverse components to form a homogeneous mixture. The process demands precision to guarantee an even distribution of each element, yielding a consistent and high-quality end product. Effective mixing is influenced by factors such as temperature, pressure, and the quality of raw materials.

Resin materials are sensitive to impurities, and any contaminants in the mixing vessel can affect the final product's quality.

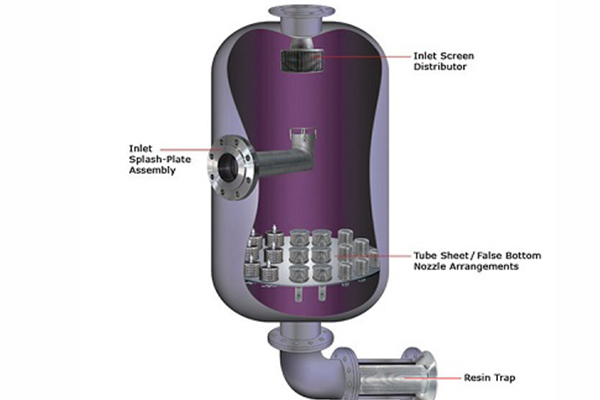

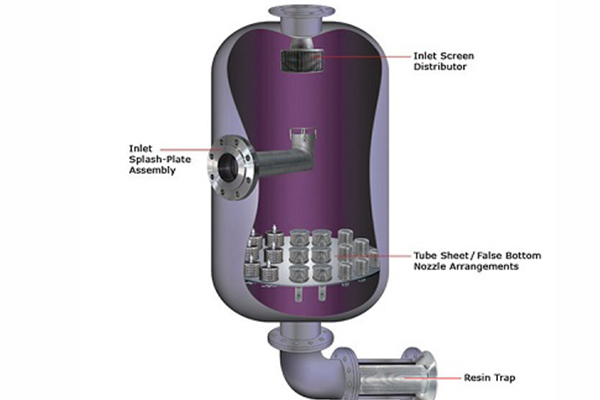

Wedge wire filter nozzles, serving as effective filtration systems, may be integrated into resin mixing vessels to eliminate impurities and ensure a clean mixing environment.

Wedge wire filter nozzles are cylindrical devices made from V-shaped wires that form a slotted surface. These nozzles are designed to allow for effective filtration and distribution of liquids in various industrial applications. The wedge wire screen design provides a large open area for fluid flow while simultaneously preventing the passage of unwanted particles.

1. Efficient Filtration:

The unique wedge wire construction ensures efficient filtration, removing particles that can compromise the quality of the resin mixture. This leads to a cleaner and more controlled mixing process.

2. Uniform Distribution:

The design of filter nozzles facilitates uniform liquid distribution throughout the vessel. This ensures that each component of the resin mixture is evenly dispersed, promoting consistency in the final product.

3. Resistance to Clogging:

The wedge wire structure minimizes the risk of clogging, even in the presence of viscous materials or particles prone to agglomeration. This reduces downtime for maintenance and cleaning, contributing to increased production efficiency.

4. Durability and Longevity:

Constructed from durable materials, our filter nozzles are resistant to corrosion and wear. This longevity translates to cost savings over time, as the need for frequent replacements is minimized.

5. Customization Options:

Resin mixing vessels are often designed to accommodate the specific needs of the resin formulation and the production process. This may include variations in size, shape, and features to match the requirements of different industries and applications.

In the chemical and pharmaceutical industry, we not only provide wedge wire filter nozzles for resin mixing vessels but also custom-produce a variety of tower internals, such as support grids and wedge wire inner pipes.

Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Stainless Steel Parabolic Screen for Mineral Processing

Stainless Steel Parabolic Screen for Mineral Processing