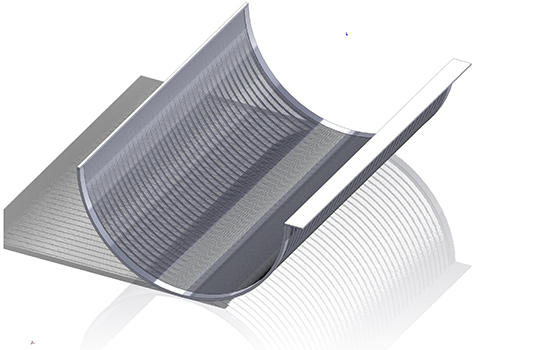

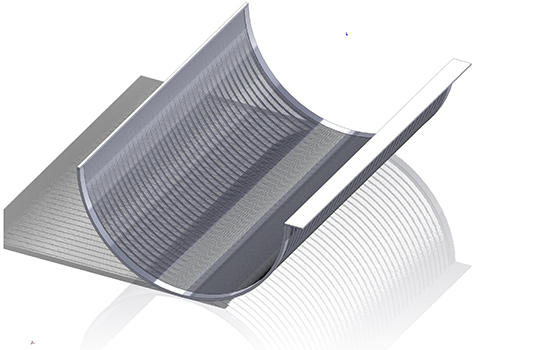

A sieve bend, a DSM screen or curved screen, is a curved, slotted wedge wire screen used in various industries for solid-liquid separation. Its primary function is to separate solid particles from liquids or slurries based on particle size.

The design of the sieve bend screen allows for effective screening and dewatering in applications such as wastewater treatment, mineral processing, food processing, and other industries.

Key Functions and Features of the Sieve Bend

1. Particle Separation

The curved screen enables the passage of liquid while retaining solid particles. The wedge wire screen features openings of a specific size that permit smaller particles to pass through, while larger particles are retained.

2. Dewatering

In addition to particle separation, sieve bend screens are frequently employed for dewatering applications. The curved design facilitates the drainage of water from the separated solids, contributing to the dewatering process.

3. High Capacity

The wedge wire screens can handle a high volume of liquid and solid material due to their design, providing a large screening surface area. This makes them suitable for applications where a significant amount of material needs processing.

4. Low Maintenance

The construction of sieve bend screens often involves durable materials, such as stainless steel, which makes them resistant to corrosion and wear. This results in low maintenance requirements and a longer operational life.

5. Customizable Design

The DSM screen can be customized to meet specific application requirements. This includes adjusting the slot size of the wedge wire screen to accommodate different particle sizes and optimizing the curve to achieve the desired separation efficiency.

Overall, sieve bends play a crucial role in separating solid particles from liquid streams, providing an efficient and reliable method for particle size classification and dewatering.

We can offer various types and sizes of sieve bend screens and other wedge wire filters for liquid and solid filtration. Contact us today!

Centrifuge Baskets - Mineral Processing Equipment

Centrifuge Baskets - Mineral Processing Equipment

Sieve Bend Screen for Starch Screening

Sieve Bend Screen for Starch Screening

Media Retention Filter Nozzle for Liquid Filtration

Media Retention Filter Nozzle for Liquid Filtration

Stainless Steel Parabolic Screen for Mineral Processing

Stainless Steel Parabolic Screen for Mineral Processing